Manufacturing Capabilities

- Home

- Infrastructure

- Manufacturing Capabilities

Metal

NACL has a fully integrated facility for Sheet Metal fabrication. Extensive backward integration measures ensure stringent quality control across all stages of manufacturing

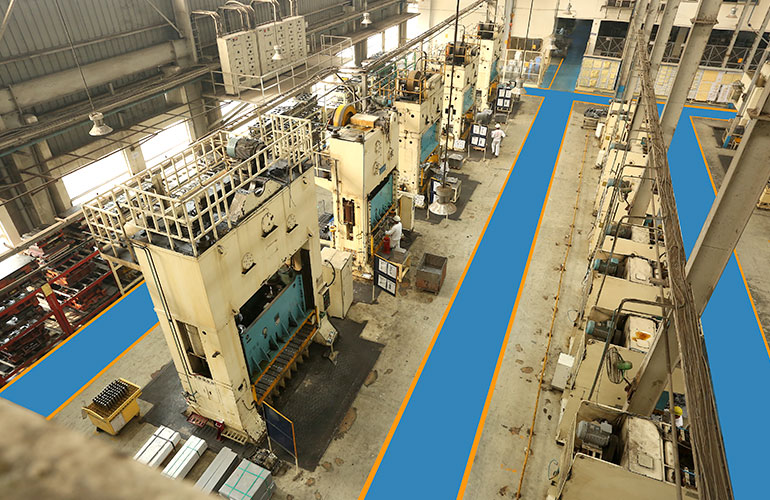

Press Shop

NACL procures sheet metal in the form of Coils and CTL (Cut to length) strips which are then processed into parts using various press machines. The plant is equipped with press machines with a capacity of up to 400 T. A total of 27 press machines can handle a wide range of Raw Materials ranging from 0.5 mm thickness to 5 mm thickness. Moreover, the plant currently uses various forms of Sheets with Tensile Strength of up to 590 kg/ m2.

Pipe Bending

NACL has over 15 Pipe Bending and Notching machines ranging from 3-axis bending to 10-axis bending. These machines are capable of bending tubes in the range of 10 mm to 54 mm, thereby covering a wide gamut of products.

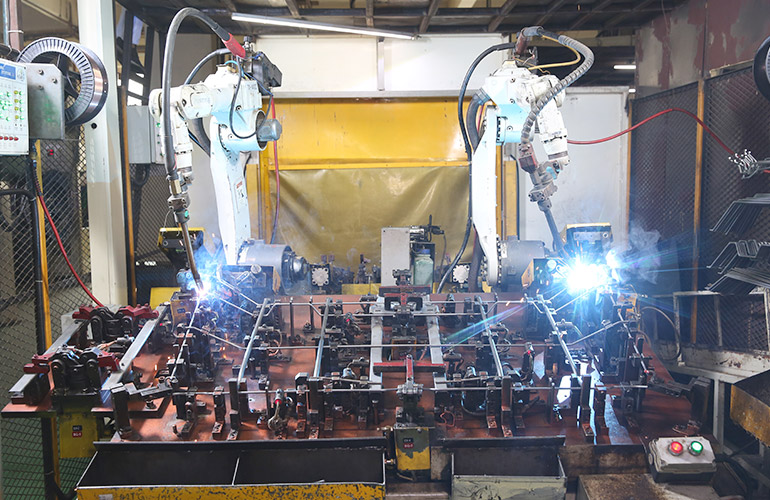

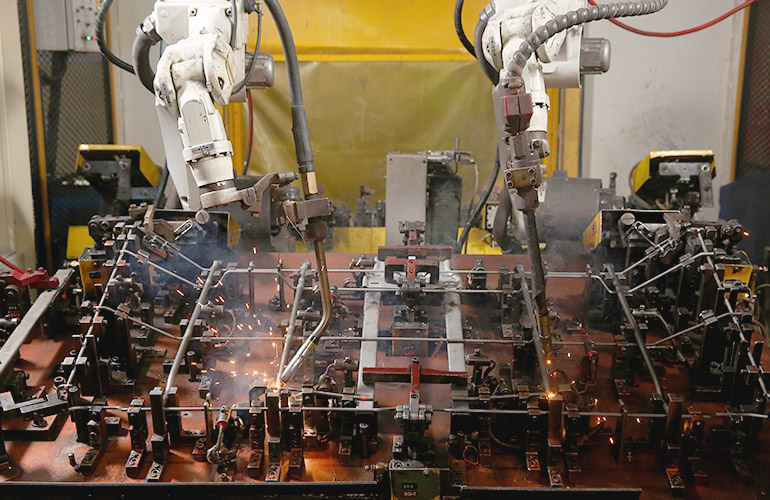

Welding Shop

NACL has a weld shop with over 30 Robots for various cells. Robots manufactured by Panasonic, Fanuc and Yaskawa perform various tasks of MAG as well as Spot Welding on complicated structures. Parts that are associated with the safety of the car (Maru-A) are produced with utmost precision and in adherence to stringent parameters, in cells that are equipped with Poka Yoke systems.

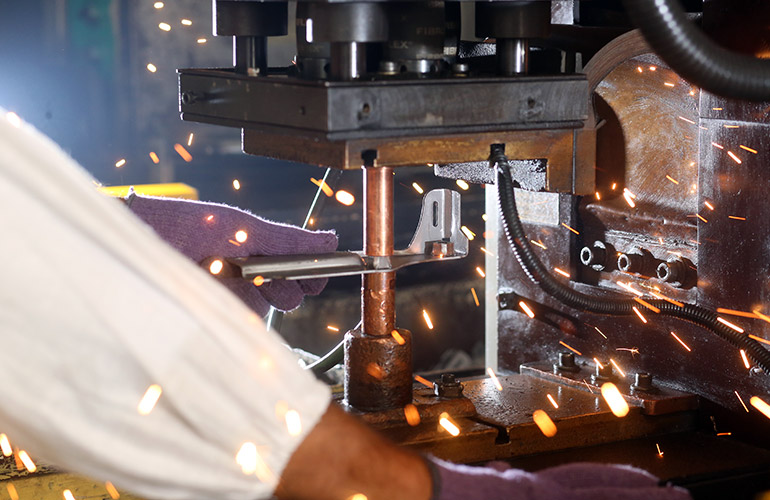

Projection Nut Welding

NACL has over 18 machines to perform Projection Nut Welding, equipped with Poka Yoke features to ensure that no nut is missed.

Testing Facilities

NACL has an in-house testing facility equipped to carry out CMM, Weld Penetration Test and various other mechanical tests on aspects like Tensile Elongation, Hardness, Profile Projector, etc.

Trims

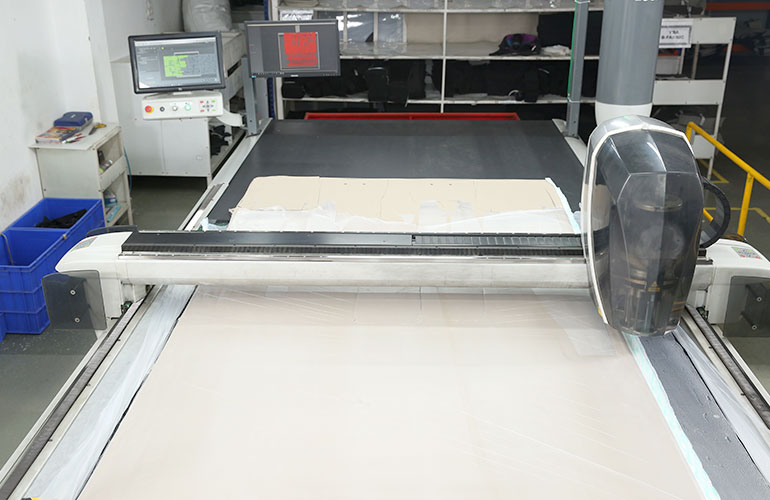

Cutting

NACL has automated cutting machines for cutting various types of material ranging from Natural Leather, Artificial Leather, PVC, Fabric, Carpets, etc. All machines represent state-of-the-art technologies from Gerber, Lectra, Bullmer and FK. For leather products, NACL has a measurement, inspection and single-layer hide-cutting machine. In fact, NACL was the first plant to procure an automated cutting machine in the Automobile Industry, way back in 2012.

Stitching

NACL has several types of Stitching Machines from Japanese manufacturers for making various types of Seat Covers (Trims). The plant includes separate lines handling sitting stitching and standing stitching for different type of products. Moreover, various types of machine areas are used; for instance, single-needle forward feed, double-needle, long arm type, post bed machines, etc.

Testing Facilities

Colour is one of the most important features of the trim. The NACL testing facility is equipped with a colour chamber with various types of lights, Colorimeter and industrial magnifying glasses to validate the design pattern and the colour of the material. Other mechanical properties like tensile elongation, flammability, etc. are checked in-house.

The testing infrastructure also includes a state-of-the-art digitizer for pattern-building and auto-nesting. This ensures exact accuracy and precision of the pattern during cutting and also acts as a quality check parameter.

Copyright © 2024 NDR Auto Components Limited. All Rights Reserved. | Privacy Policy | Disclaimer

Developed by Abacus Desk